Every organisation that operates a supply chain uses some kind of analytics software to track the performance of that supply chain. Mostly, that software is used to model the flow of goods, including modelling estimated time to destination, and places where there might be disruptions.

However, during the 2020s, supply chains are facing unprecedented challenges, climate change most of all. Supply chain software will have to adapt in order to accommodate these new risks.

In 2019, before COVID-19 struck, worldwide supply chains were designed first and foremost with efficiency in mind. [1] Companies operating supply chains, after decades of peace and stability, had stopped making contingency plans for potential shocks.

Many products were built using what is known as “Just-in-Time” supply chains, where intermediates are moved just before they are needed in the manufacturing process. This was the case for international supply chains that spanned the entire globe – and for a long time, there was no problem with doing it this way.

The advantage of Just-in-Time manufacturing is that it is efficient and allows companies to operate with low levels of inventory.

Most of the time, this is because they have been able to use analytics software to understand precisely when goods are predicted to arrive. The disadvantage is that if something goes wrong at any part of the supply chain, it can easily lead to the whole product being derailed.

For example, if a factory needs an extra week to finish an intermediate, or if consumers demand 10% more of a product one week, serious problems could occur in the entire chain. It is a type of supply chain design optimised for efficiency rather than resilience.

The shock of COVID-19

Beginning with the rise of COVID-19, there have been massive shocks that have led to global supply chains being drastically reconfigured. [2] The first has been the transition to work-from-home and socially distanced work.

Making workplaces safer has become a high priority since the start of the pandemic. This has led to increased demand for electrical equipment and sanitary items, to facilitate both work from home, and clean workspaces. At the same time, this has changed the output of various factories, and caused delays in both manufacturing and shipping.

When it comes to consumers, at a very basic level, there has been a huge shift in demand. Consumers are demanding fewer goods from, for example, movie theatres and coffee shops, but more from suppliers of food and medicine. At the start of the pandemic, and also throughout, there was a lot of panic buying from consumers who were stockpiling essential goods. All of these factors have led to supply chains being reconfigured for resilience as well as efficiency.

For disruption, the pandemic was just the start.

After COVID-19, there has been another major shock to global supply chains, that comes from rising energy prices. Since the start of the pandemic, lockdowns have led to higher demand for energy, especially in Asia. [3]

In addition, because of the wartime situation in Ukraine, there is an embargo on the supply of gas from Russia, which has driven up the price of energy even more. This has increased the cost of transport, which has made far-ranging global supply chains more likely to break or falter.

A look into the next decade

Looking towards the future, companies during the 2020s are likely to feel the effects of climate change on their supply chains. [4] Sea level rises are amongst the biggest challenges, affecting ports and shipping. Increased natural disasters such as hurricanes and floods can affect factories and production plants all over the world.

In addition to immediate practical problems with the weather, concern for the climate is already very high amongst the general public [5], and it is likely to lead soon to regulatory action over cutting carbon emissions.

In the midst of all the trouble affecting supply chains, there is also an opportunity to change how things are done for the better.

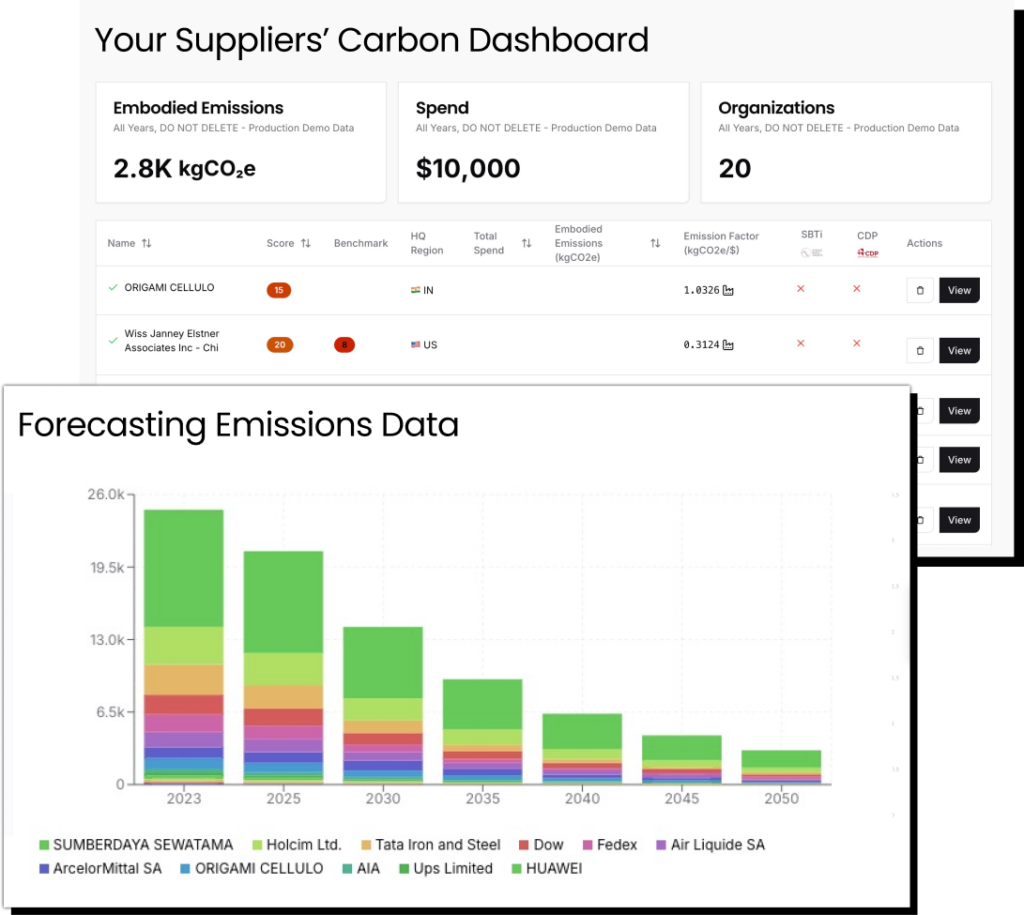

At DitchCarbon, we have created an API to measure the effects of a business’ total value chain to understand both the level of climate emissions, and the exposure to climate risks. Our simple toolkit can be incorporated into almost any business analytics tool, and can be used to drive decision-making when it comes to reducing carbon footprints.

We expect the 2020s to be a decade where the movement towards a greener planet has been catalysed, and hope our innovation in software will be part of the solution. Just as COVID-19 has contributed to energy-efficient remote work and an increased digitization of the economy, the effects of climate change are an opportunity to build new supply chains that are shorter, greener and more resilient.